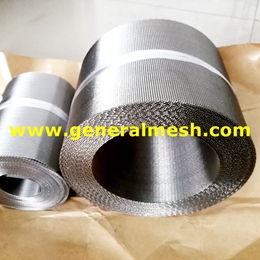

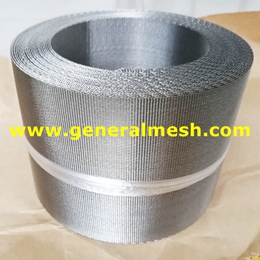

Reverse Dutch Weave Belts

Reverse Dutch Weave Belt (also known as PZ Weave) is a very strong woven product in which the larger count of wires is found in the warp and the smaller count in the shute, thus reversing the method used in plain dutch weave, twilled dutch weaves and sometimes referred to as PZ and KPZ Mesh.

Material: stainless steel wire 304, 316 or 316L.

Width of roll: 67mm, 95mm, 97mm, 127mm, 133mm, 150mm, 157mm,300mm, 400mm, etc.

Length of roll: 10m, 20m,etc.

Weaving methods: reverse plain dutch weave, reverse twill dutch weave.

Packing: wooden case.

Application:

• Filter for plastic,rubber,oil industry.

• High tensile Warp wire for Auto-Screen changers used in the Plastic Extrusion Industry.

• Rubbed edges after slitting to help with tracking for Auto-Screen changers.

• Plasma and laser cut parts to help prevent edges wire fraying.

• 100% Inspection of Wire Cloth for critical applications such as sand screens and aerospace applications.

| Reverse Dutch Weave Belts | |||

| Weave of Type | Mesh/Inch |

Wire Diameter mm |

Nominal Micron μm |

| TRD | 48 x 10 | 0.50 X 0.50 | 400 |

| TRD | 72 x 15 | 0.50 x 0.50 | 300 |

| TRD | 132 x 14 | 0.35 x 0.45 | 200 |

| TRD | 132 x 18 | 0.35 x 0.44 | 180 |

| TRD | 152 x 24 | 0.27 x 0.40 | 160 |

| TRD | 152 x 30 | 0.27 x 0.30 | 130 |

| RPD | 250 x 40 | 0.15 x 0.25 | 90 |

| RPD | 260 x 40 | 0.15 x 0.27 | 125 |

| RPD | 280 x 70 | 0.089 x 0.21 | 45 |

| RPD | 325 x 39 | 0.13 x 0.24 | 55 |

| RPD | 600 x 125 | 0.043 x 0.12 | 20 |

| RPD | 720 x 150 | 0.035 x 0.107 | 15 |

Reverse Plain Dutch Weave:

RPD has warp wires laid as close as possible one to another with relatively thin diameters, while the weft wires are very strong so called reversed weave.

Twilled Reverse Dutch Weave:

TRD is also a Reversed Dutch Twilled type, although in a twilled form. The warp wires are distributed as with RPD, although the weft wires are knocked up in a twilled weave pattern, so as not to deform the warp wires too much.

Products List

Contact Us

Add: Industrial Zone of Anping County, Hebei Province, China.Tel: +86-133-6331-6877

E-mail: sales@generalmesh.com